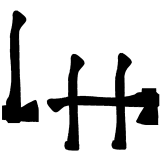

Custom 15" AZCK Hoffman Camp Axe

Price $495.00

Product Details

Blade Length 2.85

Overall Length 15.00

Closed Length 5

Weight (oz) 28.5

Source From maker

Additional Specs

Knife Type Tip Up Carry, Tip Up Clip

Blade Material ZDP-189

Blade Details Drop Point

Handle Material Wood

Other Details Engraved

About the Maker

Arizona Custom Knives

Hoffman, Liam Cole

Growing up in the rural Blue Ridge Mountains of North Carolina I was accustomed to playing outside in the woods and creeks, opening up my mind to creativity. I have always been very hands-on and creative. I would make paper dye with wild violets and mold bowls from clay dug out of the creek banks. Later on I taught myself how to macramé and learned the art of Bonsai. My mother and her family are very artistic and creative with design. My father is a hard working farmer. I believe I have both these attributes, and that when these traits are combined they fit perfectly the description of a blacksmith: hard work mixed with creative spirit. I began blacksmithing in the fall of 2008 at the age of thirteen, starting out with nothing but a pit fire and a trailer hitch for an anvil. Over the last few years I?ve worked my way up by purchasing new equipment one machine at a time and learning about the craft and science of moving steel. My parents have been extremely supportive in helping me pursue my passion. They gave me a push start by building a small brake drum forge for my fourteenth birthday. My dad took on the project of building my 200 square foot shop over a two-year period. Once this foundation was established, I had my business well under way before graduating from high school. I always get asked how and why I got started in blacksmithing at the age I did. One might think that I saw a blacksmith at a local fair or read about it in school and ran home to try it out. There was no conscious reason why I started, it's just called being a 13 year old boy. There is nothing else to it: It feels innate to me, like I was born to do it. Once I started heating up and hammering on steel, I knew it felt right. Only afterward did I discover what I was doing was called blacksmithing. Today I?m nineteen years old and an accomplished blacksmith with six years of experience. My work has sold to buyers and collectors internationally. I believe that high school hindered me in a way, since I discovered my vocation at such a young age. Getting an education is imperative, but at the same time it felt nearly obsolete for me to take honors classes. I was already working 35 hours a week after school and on weekends, making both school and work life challenging. Add to that several years in Boy Scouts, achieving Eagle Scout at seventeen. I truly believe in hard work for building character and maturity. The secret to success is passion, of which I?m fortunate to have plenty for blacksmithing. Work hard and love what you do, and it will all seem like play!

Hoffman Blacksmithing

Growing up in the rural Blue Ridge Mountains of North Carolina I was accustomed to playing outside in the woods and creeks, opening up my mind to creativity. I have always been very hands-on and creative. I would make paper dye with wild violets and mold bowls from clay dug out of the creek banks. Later on I taught myself how to macramé and learned the art of Bonsai. My mother and her family are very artistic and creative with design. My father is a hard working farmer. I believe I have both these attributes, and that when these traits are combined they fit perfectly the description of a blacksmith: hard work mixed with creative spirit. I began blacksmithing in the fall of 2008 at the age of thirteen, starting out with nothing but a pit fire and a trailer hitch for an anvil. Over the last few years I've worked my way up by purchasing new equipment one machine at a time and learning about the craft and science of moving steel. My parents have been extremely supportive in helping me pursue my passion. They gave me a push start by building a small brake drum forge for my fourteenth birthday. My dad took on the project of building my 200 square foot shop over a two-year period. Once this foundation was established, I had my business well under way before graduating from high school. I always get asked how and why I got started in blacksmithing at the age I did. One might think that I saw a blacksmith at a local fair or read about it in school and ran home to try it out. There was no conscious reason why I started, it's just called being a 13 year old boy. There is nothing else to it: It feels innate to me, like I was born to do it. Once I started heating up and hammering on steel, I knew it felt right. Only afterward did I discover what I was doing was called blacksmithing. Today I'm twenty years old and an accomplished blacksmith with seven years of experience. My work has sold to buyers and collectors internationally. In June 2016, I traveled to Brooklyn, NY to appear on History Channel's Forged in Fire. There, I forged a Kora sword and became the youngest to win Forged in Fire against ABS Master Bladesmith Josh Smith.

Hinderer, Rick

In the mid 1980’s Rick Hinderer began his knife making journey making art knives in a small 14′ x 18′ turkey coop with none of the modern amenities, like heat or running water! Art knives are a far cry from the tactical scene which Rick is so deeply entrenched in now. Over the years his meticulous attention to knife design and knife making, coupled with his real world experience as a Fire Fighter / EMT sets him apart from the rest. Rick’s design philosophy is deeply rooted in his experience with using his knives as part of his first responder tools. That catalyst of change from art knives to hard use tactical was after Rick joined the rescue dive team. He really began to look at knives and designs more as hard use tactical tools than works of art. Rick began changing over from old world knife making techniques to modern CNC precision manufacturing. With the combination of designing art knives, and his real world experience as a first responder, this unusual perspective allows him to design hard use tactical folders that are not only aesthetically pleasing to the eye, but extremely comfortable in the hand. All of Rick’s products are engineered to go the distance when it counts the most whether it be when life is on the line, or you just need a good cutting tool.